The Basics of Touch Technology

At its core, a touchscreen is an interface that allows users to interact directly with a display without the need for a keyboard or mouse. Over the years, many touch technologies have been developed, but three have proven most influential: resistive touch, infrared touch, and capacitive touch. In recent years, capacitive touch has become the benchmark across most applications. But what sets it apart from the alternatives and does it actually work?

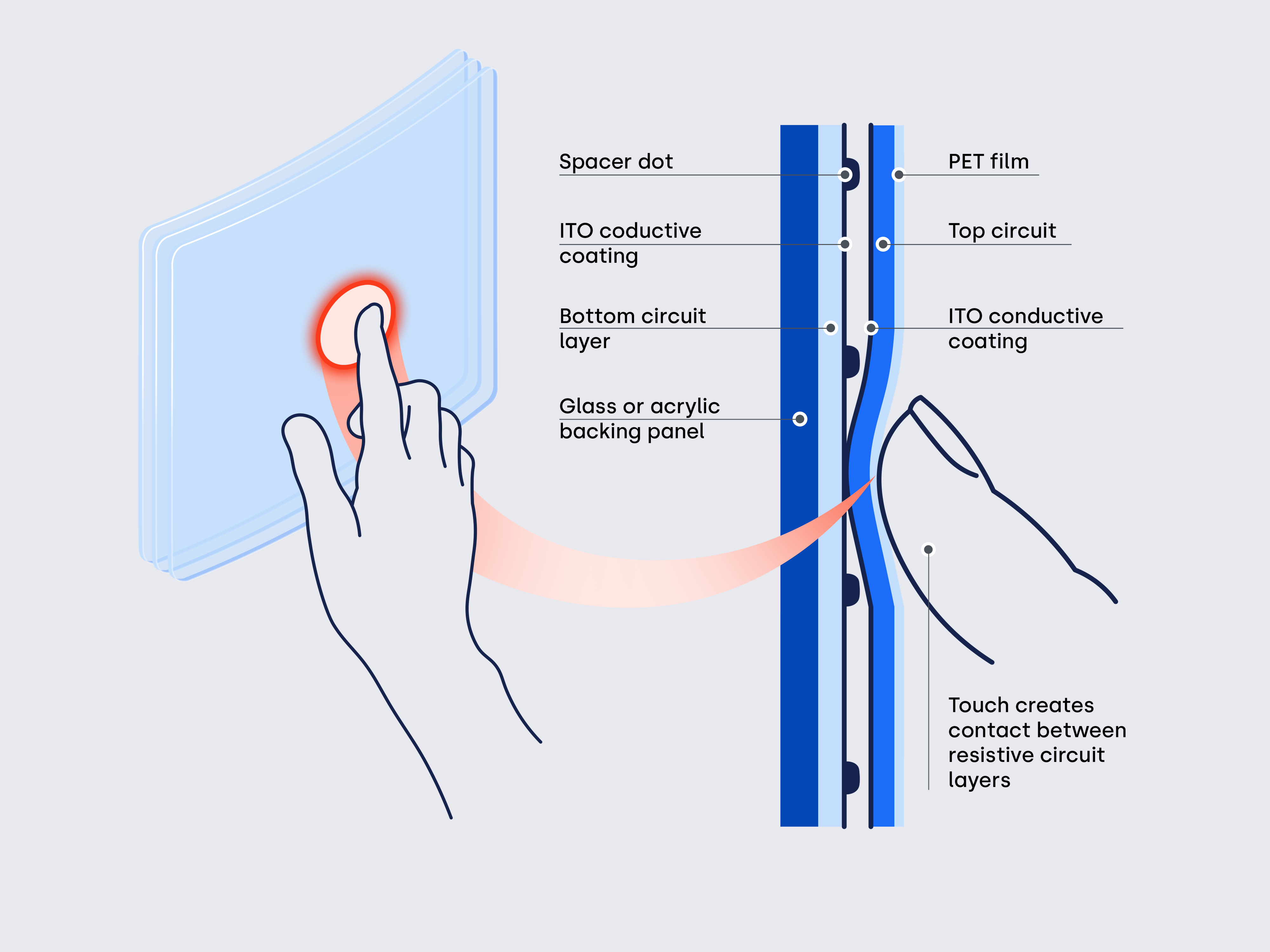

Resistive Touch

Resistive touchscreen technology relies on pressure applied to two transparent conductive layers, typically made of indium tin oxide (ITO) and separated by a thin spacer. When a finger or stylus presses against the screen, the layers make contact, creating a voltage change at that point. The controller calculates the exact coordinates from the voltage division across the X and Y axes, and the system registers a touch.

Resistive touch was once common in payment terminals, machine interfaces, and ATMs. These systems are durable and dependable, but they support only single-touch input and are prone to wear over time. Because they respond to pressure rather than conductivity, resistive screens are immune to electromagnetic interference (EMI) and work reliably with gloves or a stylus. This reliability is why they remain in use in certain industrial and medical environments, despite their optical and functional limitations.

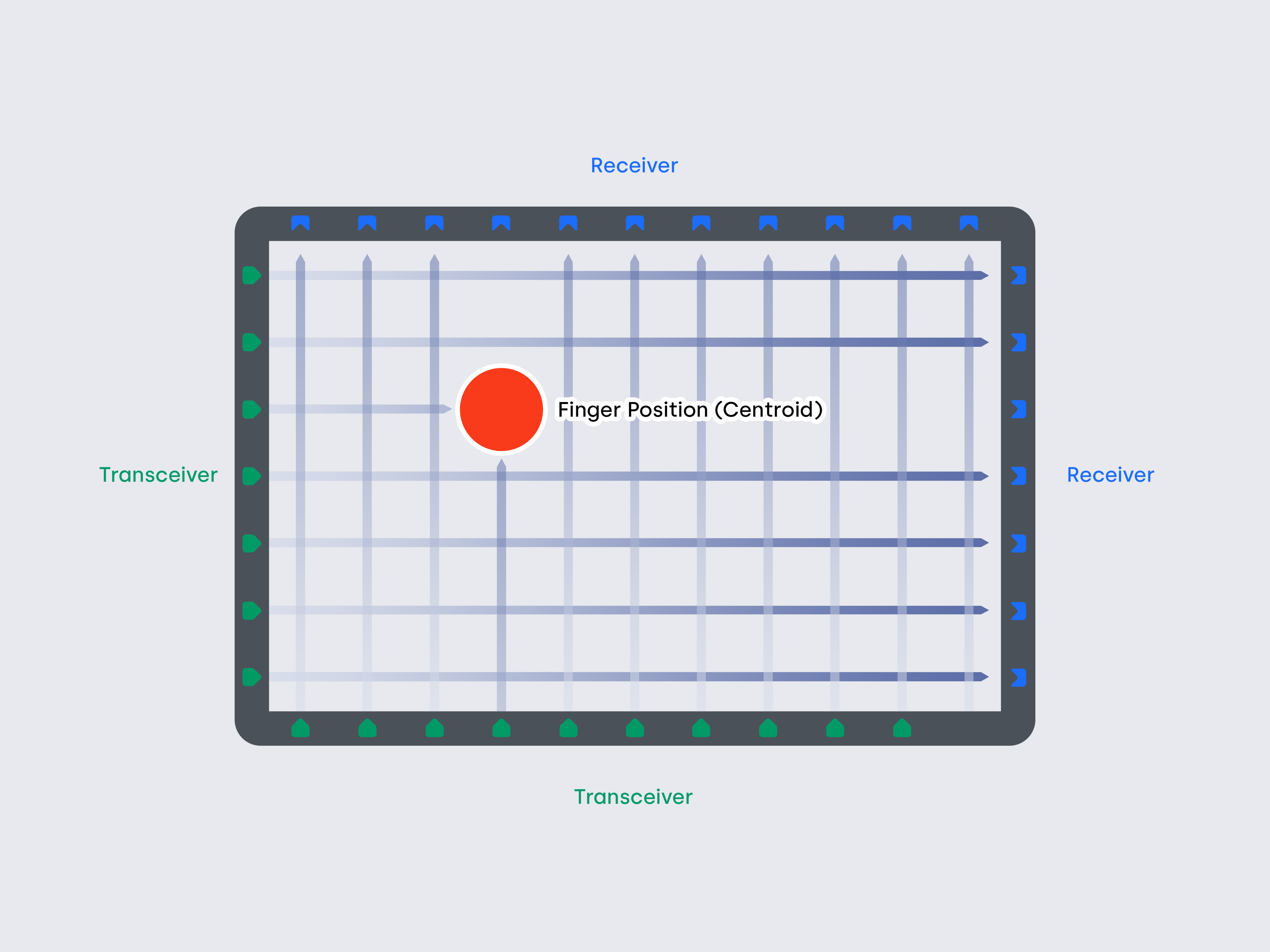

Infrared Touch

Infrared touch detects input using a grid of light beams around the display surface.. Infrared emitters and receivers are positioned around the frame of the screen, creating an invisible grid of light beams across the display. When a finger or object makes contact, it blocks specific horizontal and vertical beams. By identifying which beams are interrupted, the controller calculates the precise coordinates of the touch.

Because of its scalability, infrared touch is often used in large-format displays such as interactive whiteboards and signage where cost efficiency is critical. However, they are less precise and can be disrupted by dust, dirt, or bright light. Maintaining accuracy also requires careful alignment and protection against contaminants, which adds complexity when integrating IR touch into sealed or outdoor housings.

Capacitive Touch

While resistive and infrared have each played their part in the evolution of touch technology, the real breakthrough came with capacitive touch. Unlike resistive systems that depend on pressure or infrared grids that rely on interrupted light beams, capacitive touch uses the natural electrical properties of the human body to detect interaction. This shift in principle allowed for thinner designs, brighter displays, and faster, more precise input. There are two main approaches within this category: surface capacitive touch and projected capacitive touch (PCAP).

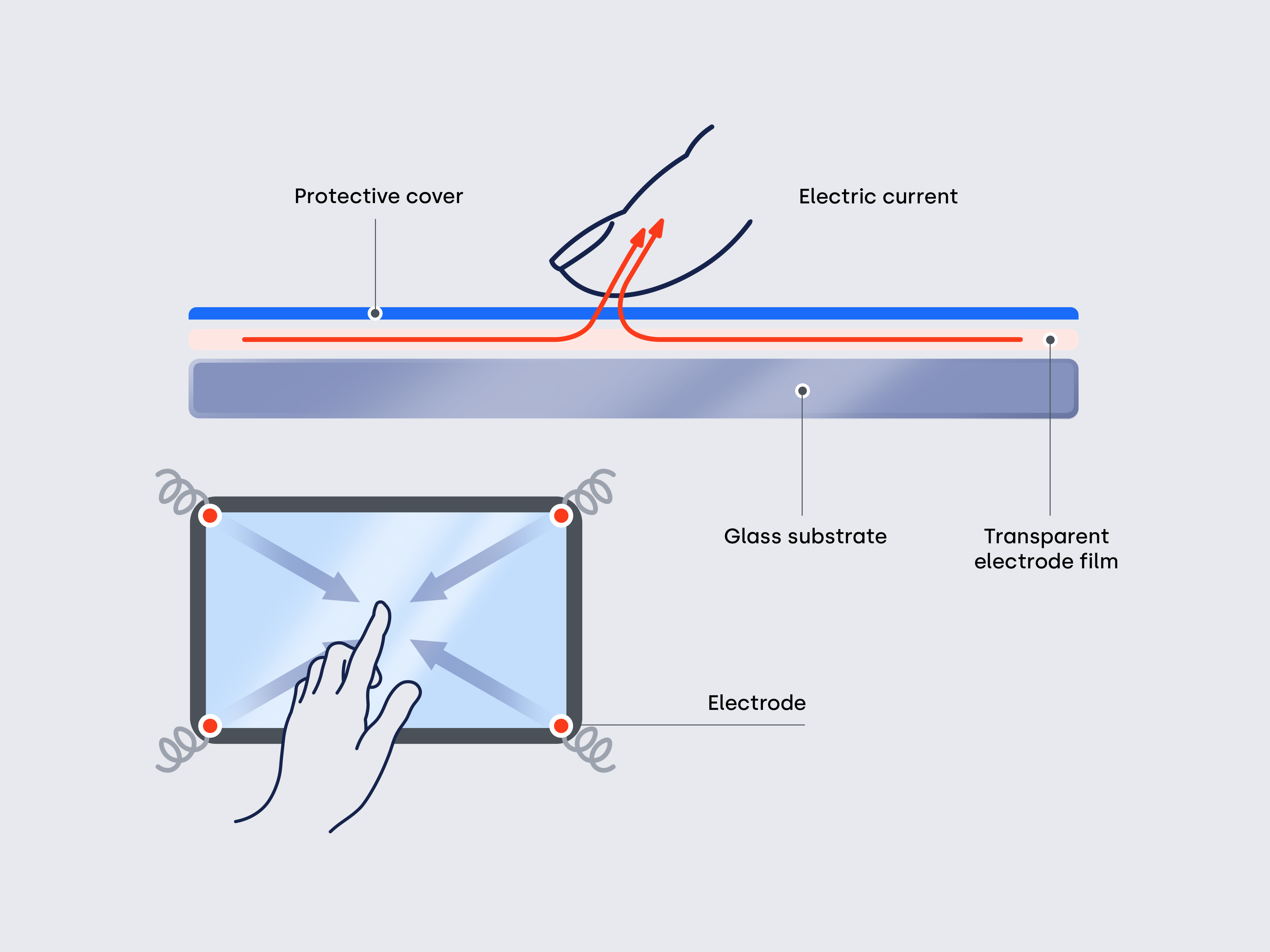

Surface Capacitive Touch

Surface capacitive touchscreens work by applying a transparent conductive coating to the glass surface. Electrodes are placed along the corners or edges to generate a uniform electric field across the screen. When a finger makes contact, the human body conducts a small amount of current, which disturbs the electric field. The touchscreen controller then measures the resulting changes in current at the corners or edges and uses this data to calculate the exact touch coordinates.

Projected Capacitive Touch (PCAP)

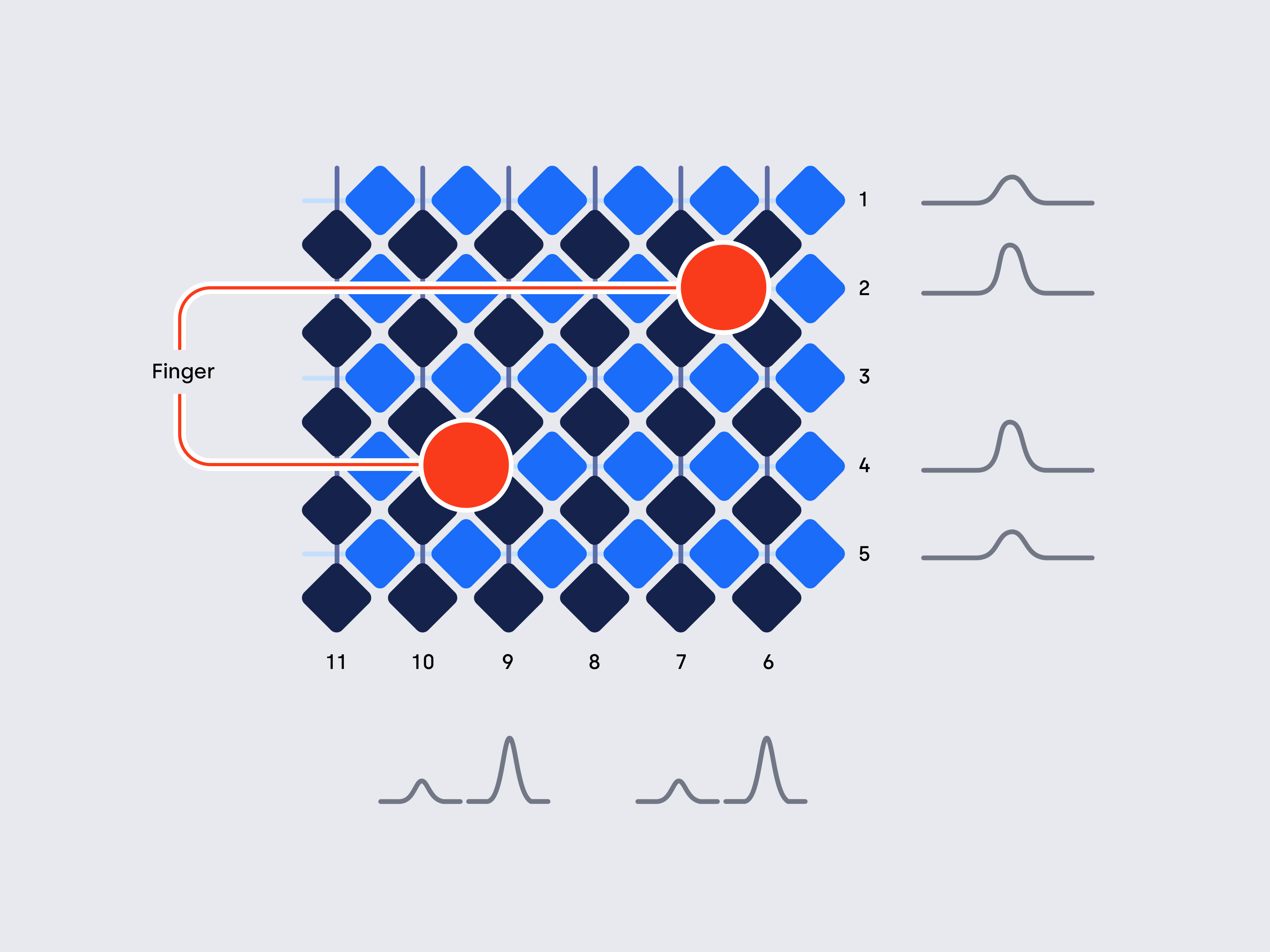

Where surface capacitive touch relies on current measured at the edges, projected capacitive touch takes the principle a step further. Instead of a single conductive layer, it uses a grid of electrodes spread across the glass. This design allows for higher precision, faster response and true multi-touch capability.

A useful way to picture it is as a fine mesh of invisible wires running horizontally and vertically across the surface. Together, they form an electrostatic field. When a finger touches the glass, its natural electrical charge disturbs this field exactly at the crossing point of the wires. The controller picks up the disturbance instantly and calculates the coordinates. Because thousands of intersections are monitored at once, the system can track multiple touches in real time, enabling gestures such as pinch to zoom, rotation and swiping. This principle can be implemented in two different ways, known as self-capacitance and mutual capacitance.

- Self-Capacitance: On the glass, ITO electrodes are patterned horizontally and vertically, each forming self-capacitance with ground. When a finger touches the screen, it increases capacitance at that point. The system combines the changes on the horizontal and vertical axes to determine the coordinates. Self-capacitance is accurate for single-touch input, but when multiple fingers are present it produces “ghost points,” or false touches, which prevents true multi-touch operation.

- Mutual Capacitance: Mutual capacitance uses a similar electrode layout, but capacitance is formed at the intersections of horizontal and vertical electrodes. A finger touch disrupts the field at these intersections, changing the measured signal. During operation, horizontal electrodes send out signals while vertical electrodes measure the changes, allowing the controller to triangulate precise coordinates. This design supports accurate multi-touch, which is why mutual capacitance has become the industry standard in most modern applications. At Beetronics, we have standardized all of our touchscreens on projected capacitive (PCAP) technology because it provides the most reliable combination of precision, responsiveness, and consistent touch performance.

PCAP Architectures and Variations

Projected capacitive touch is based on a single underlying principle, but it can be realized in different ways to meet specific requirements. The choice of materials, sensor layout and construction method influences performance, durability, thickness and cost. These variations can be grouped into two main categories: sensor architectures, which define how the conductive grid is formed, and construction methods, which determine how the touch layer is integrated into the display.

Sensor Architectures

- DITO (Double-ITO) / SITO (Single-ITO): Two common indium tin oxide (ITO) touchscreen designs. Both work by detecting tiny changes in capacitance where the conductive lines cross, which is how the screen identifies a touch. DITO uses two separate layers, one for each axis, allowing for highly precise detection, while SITO places both axes on a single layer, making the screen thinner and more cost-efficient, though with slightly less precision.

- Metal Mesh: An ultra-fine grid of metallic wires forming the electrode pattern. Offers high conductivity, durability and flexibility, making it suitable for large-format or curved displays.

- Nanowire: Networks of conductive nanowires, often silver. They combine high transparency and flexibility with fewer visible patterns than metal mesh, but can face challenges with uniformity and long-term stability.

Construction Methods

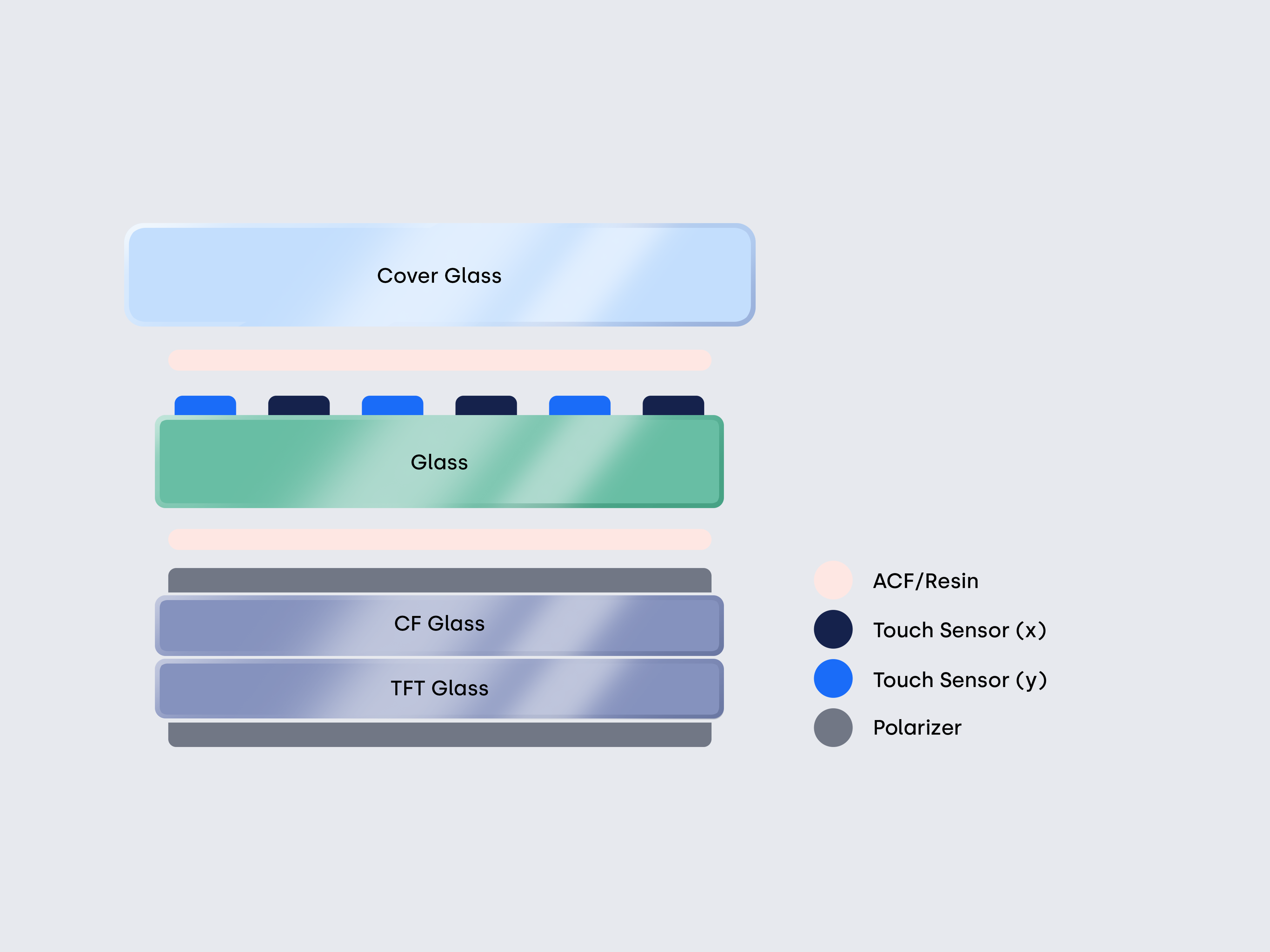

- GG (Glass–Glass): Two laminated glass layers, one protective cover and one with ITO electrodes. Highly durable, scratch-resistant and stable, making it suitable for high-reliability applications. That’s why at Beetronics all of our touchscreens are built with a glass–glass PCAP construction, which provides the best balance of touch accuracy, ruggedness, and consistent performance required in demanding professional applications.

- GFF (Glass–Film–Film): Combines a cover glass with two ITO-coated films. Often optically bonded to the LCD to eliminate air gaps, which improves sunlight readability, impact resistance and long-term reliability.

- OGS (One Glass Solution): Integrates electrodes directly into the cover glass for thinner, brighter displays. Requires reinforcement for durability, which increases cost and limits use in rugged applications, but remains attractive for slim designs where optical performance is key.

- In-Cell / On-Cell: Electrodes integrated inside or on top of the LCD stack. Reduces thickness and improves optical clarity, common in slim consumer devices. Higher integration cost, limited availability and repairability make them less suited for professional systems.

- Flexible PCAP: Uses bendable substrates to enable foldable or wearable screens.

Why Projected Capacitive Touch Remains the Benchmark

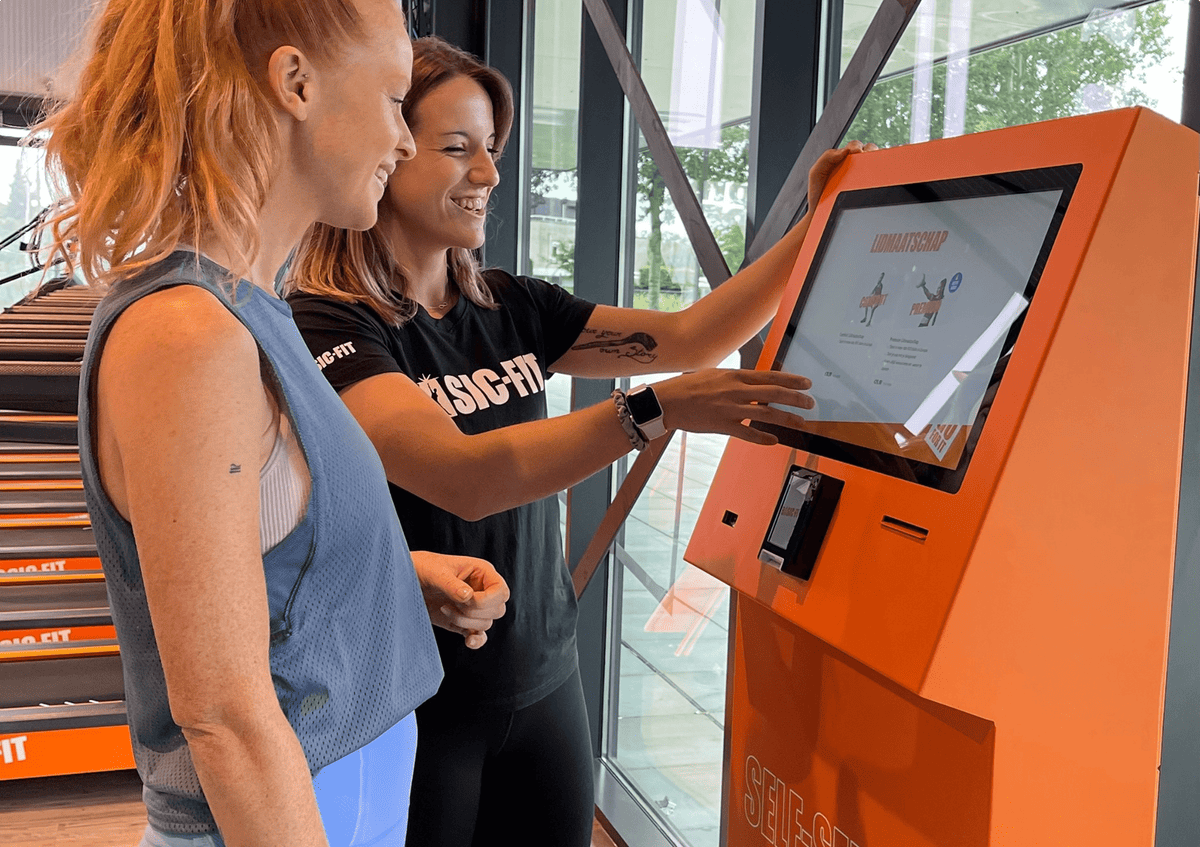

From consumer electronics like smartphones and tablets to self-service kiosks, machine interfaces, and parking meters, projected capacitive touch has become the standard across industries. The reason lies in a combination of advantages that other technologies cannot match.

- Accuracy and clarity: With fewer layers between the user and the display, PCAP responds almost instantly. The result is a fast, natural touch experience with sharp and bright image quality.

- Multi-touch capability: Every intersection in the electrode grid is measured independently, allowing multiple touches to be tracked at once. This makes gestures like scrolling, zooming, and rotation smooth and intuitive.

- Durability and versatility: The solid glass surface is strong, scratch-resistant, and can be sealed against dust and moisture. With proper tuning, PCAP also works reliably with gloves, styluses, or even in wet conditions.

Together with the flexibility offered by different sensor architectures and construction methods, these qualities explain why PCAP has become the trusted choice in both consumer products and professional systems where performance and long-term reliability are critical. Looking ahead, innovations such as graphene-based conductors, advanced haptics, and deeper sensor integration may expand what is possible. Yet for the foreseeable future, projected capacitive touch will remain the dominant technology in most touch applications.

Want to learn more about touch technologies or explore which type of touchscreen is best suited for your application? Our specialists are happy to discuss your options and answer any questions about Beetronics display solutions.